How Diamond Is Cut | Full Detailed Explanation

How Diamond Is Cut | Full Detailed Explanation

Key Highlights:

- Diamonds: Tough but transformable – Despite their hardness, diamonds undergo a precise cutting process to become sparkling gems.

- Hand vs. Machine: A blend of tradition and technology – Skilled artisans use both time-honoured hand-cutting techniques and modern machinery for optimal results.

- A Global Journey: From mines to major trading centres – Rough diamonds travel from mines to hubs like Antwerp, Dubai, and Tel Aviv before reaching cutting and polishing centres like Surat and Guangzhou.

- The Stages of Transformation: A delicate dance – The cutting process involves meticulous steps like planning, marking, cleaving/sawing, bruting, blocking, crowning, polishing, and final inspection.

- Unveiling the Brilliance: How cuts create magic – A well-cut diamond maximizes light reflection and dispersion, resulting in the dazzling sparkle and fire we cherish.

- Beyond the Basics: Exploring a world of cuts – The round brilliant cut is just one option; various cuts like emerald and princess cater to diverse preferences.

Diamonds may be the hardest natural material on Earth, but that doesn’t mean they’re invincible. In fact, transforming a rough diamond into the sparkling gem we know and love requires a skilled and precise cutting process. Let’s delve into the fascinating world of diamond cutting, exploring the techniques, locations, and the impact this process has on the final value of a diamond.

Shaping the Diamond: Hand vs. Machine

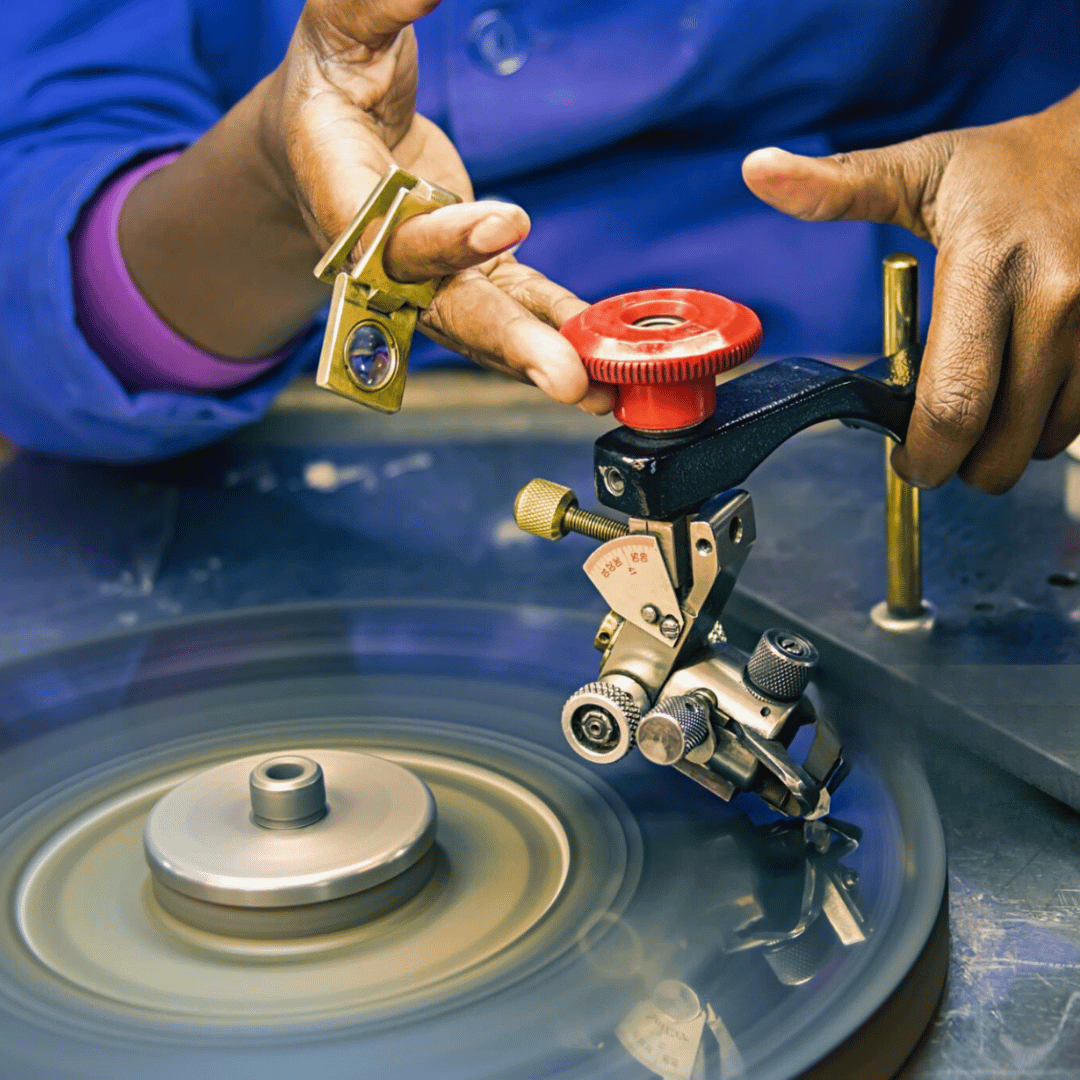

Diamond cutters are true artisans, wielding both traditional hand-cutting techniques and modern machinery. While machines offer precision and efficiency, hand-cutting remains a revered craft demanding exceptional skill and experience.

The Journey of a Diamond: From Mine to Market

Rough diamonds embark on a global journey before gracing your jewellery. Major trading centres like Antwerp, Dubai, and Tel Aviv handle the rough stones, while cutting and polishing often occur in locations like Surat (India) and Guangzhou (China). These hubs have emerged as leading players in the diamond industry, contributing significantly to the global polished diamond market.

Unveiling the Magic: How Diamonds Get Their Sparkle

The cutting process plays a crucial role in a diamond’s brilliance and fire (play of colours). A well-cut diamond allows light to enter through the crown, reflect off the facets, and disperse as a dazzling spectrum of colours, creating the signature sparkle we love.

Beyond the Basics: Exploring Different Diamond Cuts

The round brilliant cut is just one of many popular diamond shapes. Each cut, from the elegant emerald to the radiant princess, offers a unique brilliance and fire, catering to different tastes and preferences.

The Stages of Diamond Cutting: A Delicate Process

The transformation of a rough diamond involves several meticulous steps. Here’s a simplified look at the round brilliant cut, the most popular diamond cut:

- Planning: Modern software assists in mapping the optimal cut for the rough stone, maximising yield and brilliance.

- Marking: The outline of the ideal cut is meticulously marked on the diamond.

- Cleaving/Sawing: The rough stone is either cleaved along its natural grain (weakest point) or sawed using a diamond-coated blade or laser.

- Bruting: The girdle, the outer rim of the diamond, is shaped using spinning wheels or discs coated with diamond abrasive.

- Blocking: The eight main facets of the pavilion (lower half) are formed.

- Crowning: The eight main facets of the crown (upper half) are created.

- Polishing: Each facet is meticulously polished to achieve maximum light reflection and brilliance.

- Inspection: The finished diamond undergoes a final examination to ensure it meets the desired quality standards.

Conclusion

In conclusion, diamond cutting is an extraordinary process that merges technical expertise with artistic vision. Each rough diamond has the potential to become a dazzling gem, but it takes the skilled hands of a master cutter to unlock its true brilliance. This intricate procedure, involving meticulous planning and precision, shapes the stone to reflect light in the most mesmerizing way possible. From deciding on the optimal shape to carefully crafting every facet, diamond cutting is a testament to human creativity and innovation. It transforms nature’s raw creation into a symbol of timeless beauty and value, ensuring that diamonds remain cherished heirlooms passed down through generations. The artistry behind diamond cutting not only enhances the stone’s appearance but also preserves its legacy as a treasure admired for centuries.